Problem:

Our client, concerned about the repetitive motion their operators were performing daily, approached RG Luma in search of a simple, cost-effective solution to help prevent repetitive strain injuries. The task involved manually winding a lever to bend steel strips into shape—a process repeated numerous times throughout the day. The goal was to develop a compact, easy-to-use solution that would reduce physical strain while being small enough to fit on a desk and allow the operator to remain seated during operation.

Solution:

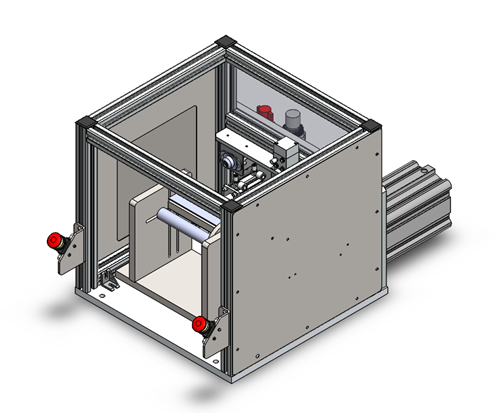

The design needed to eliminate the risk of introducing a new repetitive strain issue while still allowing operator involvement. One of the key challenges was maintaining a compact footprint that allowed easy access for loading and unloading steel strips. To address safety without relying on bulky guarding—which would have made the machine too large and less accessible—the solution incorporated a two-hand control system. This required the operator to press two separate buttons simultaneously to activate the machine, ensuring hands were safely away from moving parts during operation.

To keep the solution cost-effective and straightforward, the mechanism employed a rack-and-pinion system powered by a single pneumatic cylinder to rotate and bend the part into shape. By avoiding electronics and relying solely on pneumatic components, the design remained simple, reliable, and desk-friendly—requiring no wiring or complex electrical systems. The machine’s minimal setup—requiring only an airline connection—facilitates easy relocation when necessary.